Contributing $ 6

Thank you for cooperating!

The cooperative crua exists thanks to all the people who have supported it. You're one now. Thank you!

Remember that you can deduct up to 80% of your contribution, calculate it here.

> 01 Co-financiers

Goteo ha construido una historia única en el mundo del micromecenazgo. ¿Quieres seguir formando parte de ella?

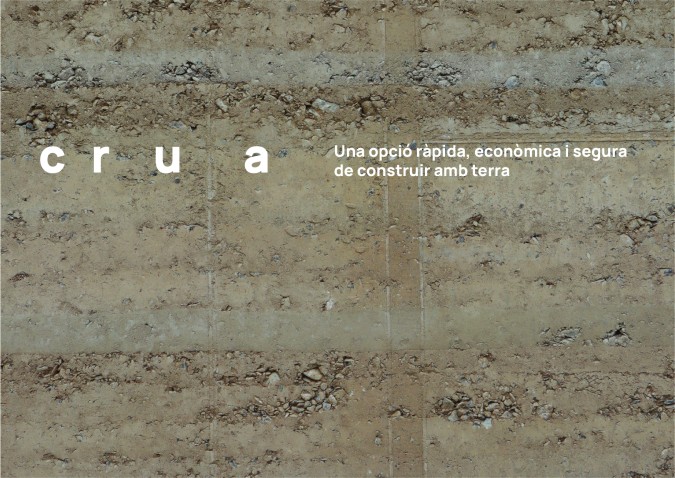

Crua: cooperating to change the future of construction materials.

Min.

Min.

Opt.

Opt.

The cooperative crua exists thanks to all the people who have supported it. You're one now. Thank you!

Remember that you can deduct up to 80% of your contribution, calculate it here.

Thank you for taking the step! We will include your name in the list of patrons of our website.

Remember that you can deduct up to 80% of your contribution, calculate it here.

Cooperative spirit! You will receive a totebag made from organic and fair trade cotton.

Remember that you can deduct up to 80% of your contribution, calculate it here.

Thank you for your contribution! You will receive a totebag and a t-shirt made from organic and fair trade cotton.

Remember that you can deduct up to 80% of your contribution, calculate it here.

Do not worry, you will not be left without a bag and t-shirt, but you will also be able to enjoy a visit to the crua facilities, which will have been possible thanks to you, plus the visit to an earth project by the team.

Remember that you can deduct up to 80% of your contribution, calculate it here.

Join us in the transformation of the construction sector. With your contribution, you have not only helped make this transformation ever closer, but you will learn to formulate and ram a block of compacted earth!

Remember that you can deduct up to 80% of your contribution, calculate it here.

You seem to be committed to the environment! Thank you for your contribution! We will help you think about how to improve climatically the place where you live, enjoy a personalized advice for your home or your place of work.

Remember that you can deduct up to 80% of your contribution, calculate it here.

Together we make the change! We are so grateful that we invite you to a workshop of formulation and technique of rammed earth wall, and we will also help you think about how to climatically improve the place where you live, enjoy personalized advice from your home or your workplace. Don't worry, you will also receive a totebag and a t-shirt made from organic and fair trade cotton.

Remember that you can deduct up to 80% of your contribution, calculate it here.

Are you solidary and also have a space to rehabilitate or build? With your contribution you have achieved a draft project of bioconstruction of the space of your dreams! Once the campaign is over, we will meet to start projecting.

Remember that you can deduct up to 80% of your contribution, calculate it here.

Let's work together! Thank you very much for wanting to be part of the project, your space will be a pilot space of our blocks, soon you will be able to enjoy a space made to measure of your needs and most importantly, of earth!

Remember that you can deduct up to 80% of your contribution, calculate it here.

A project that wants to contribute to the decarbonisation of the construction sector with a system of large format pieces of rammed earth

Task

Task

|

Minimum | Optimum |

|---|---|---|

|

Campaign cost

The matchfunding campaign is designed to publicize our project. This part includes the coordination, design and production of graphic materials.

|

$ 1,175 | |

|

Company marketing

Getting to know new products in the construction market is a challenge that we want to bet on, it involves generating trust and security to our customers in order to achieve position ourselves as recognized agents. This item includes brand accompaniment, the website, and digital and media positioning.

|

$ 17,630 | |

|

Industrial property, rights and applications

The resulting system must be protected and validated by a CITE: European Technical Identity Document, a favorable technical evaluation of the suitability of a product for the assigned use, based on compliance with the Essential Requirements foreseen for the works in which the product is used. This protection, such as the CE marking and the appearance of the product in emissions calculation programs and measurements used in construction represent a large part of the initial budget of going to the market with a construction product. This item represents the cost of this first year labeling on the market.

|

$ 47,012 | |

|

Salaries

50% of the labour costs of 3 people full-time for the technical development and prototyping of the product.

|

$ 35,259 |

Material

Material

|

Minimum | Optimum |

|---|---|---|

|

Rewards

Production and distribution of bags and shirts. Management and planning of the services offered as a reward to plan the workshops and advice days.

|

$ 1,175 |

Infrastructure

Infrastructure

|

Minimum | Optimum |

|---|---|---|

|

Prototype

Manufacture, systematization and testing of prefabricated earth block. This item contemplates the design and optimization of the blocks of raw earth and the derived test processes (loading tests, acoustic and hygro-thermal) to obtain the final product that we will put on the market.

|

$ 4,701 | |

|

Constructions

Crua already has a warehouse to develop the product, but it must be updated for the new needs that will lead us to be more efficient and lower the price of the blocks in order to make them affordable to the maximum population

|

$ 17,630 | |

|

Machinery

In order to make the work of the manufacturer more pleasant, we need to invest in the mechanization and automation of the tools. That is why we will work on the development of the necessary machinery made to measure for the manufacture of our blocks and thus improve the working conditions of our operators.

|

$ 58,765 | |

| Total | $ 7,052 | $ 183,347 |

The architecture studios Arqbag cooperative and Edra architecture km0 together with the construction company Coeco cooperative starting a new project, the consultancy and prefabrication of construction products of raw earth and with the focus on reducing emissions from the construction sector and generating new decentralized employment opportunities. The protagonist of the project: construction with earth.

Catalonia has a long tradition of construction with earth, from Ponent to the Empordà, however, the industrialization of construction materials has eclipsed the traditional techniques such as construction with raw earth. So, could we recover the earth as a building material adapted to the current needs?

Construction with raw earth has many benefits for the habitability of the spaces around us. It is not only a material that allows structural walls to be made, but that, due to its mass, has a lot of thermal inertia, which means that it stores heat in winter (and gradually releases it towards the interior regulating the temperature), as well as in summer the heat stored in the wall during the day is released to the outside with the freshness of the nights. In addition, it has the ability to regulate the humidity of spaces and to breathe. That is why earth is conceived as one of the healthiest materials for construction. The earth is compacted humid, and when dry, it raises great resistance and hardness, which also protects itself from the rain and wind.

The land is revalued when contacting waste management companies, with a clear commitment to circularity and low environmental impact. It is mainly a raw matter and, therefore, not cooked, with the energy saving and the null contamination that this entails. Finally, a prefabricated system is proposed that allows us to improve working conditions and have greater control of costs and deadlines at the time of execution of the work.

The commitment to prefabrication is crucial for the updating of traditional, conscious and responsible techniques with the climate context and proximity resources. The fact of opting for the industrialization of the earth has a primary objective: to ensure that its qualities can be available to more people and that the material is a competitive alternative to the current construction systems, both at the cost level and at the speed of construction. In this way, it is intended to achieve a catalog of options of low environmental and healthy impact construction materials at everyone's reach.

Our goal is to be able to produce large format compacted earth prefabricates. We have the expertise of a team that has been working with the earth for more than 20 years, studying its structural, biological and environmental qualities, and developing a feasibility plan and business model that not only offers a healthy and safe product to the market but is able to generate a network of decentralized jobs.

Now is the time to start the project, and that is why we need to generate the infrastructure, update the regulations of the construction sector and disseminate these new (or not so new) ways of building:

– low impact at adjusted prices – popularizing low environmental impact construction and dissociating the concept of sustainability of products accessible to a minority of society, can be achieved thanks to the industrialization of the system, reducing a hard labour derived from the current manual process to achieve rammed earth elements and being able to increase its production.

— circularity — to ensure that a large part of the raw material we use in the construction world comes from prior waste management instead of using extraction material. To take away from the earth the label of “waste” and to put on it that of “resource” is one of the social needs that our product aims to cover.

And this is how we want to achieve it:

1—the raw material is obtained from excavation companies and waste management companies. The earth they currently receive is reused only to cover and naturalize old landfills, this project gives it value and makes it another resource.

2—we place the epicenter of our production in the city of Balaguer, where we have a warehouse where we can store the earth and manufacture the parts on demand. The strategic position of the factory allows us to cover a large amount of the territory and reach projects within a radius of 200 km, an optimal distance to maintain the low environmental impact of the product.

3—we offer as a technical office two services to be able to implement this system. A first comprehensive service of drafting the entire project (architectural, accompaniment, and environmental advice); and the second, the adaptation of the construction system to projects that want to opt for prefabricated earth as construction material, promoted from a owned meterial laboratory.

4—the construction of the prefabricated structure of rammed earth is carried out with the own means and personnel in our facilities.

5—the finished product has a last warranty and maintenance service.

The national and European environment increasingly tends to the implementation of regulations and guidelines that lead us towards a construction of low environmental impact, industrialized and with products and materials that meet high requirements of circularity. In this present and immediate future is where we detect the opportunity to generate a product that helps us to make this transition process towards a more conscious construction with the environment that surrounds us.

With the common objective of contributing to the decarbonization of the construction sector and the generation of quality and decentralized employment, the industrialization of compacted earth is an essential solution, since another great interest of the land are its almost zero CO2 emissions, a global objective to make a transition towards decarbonization through models, materials, systems and technology that can make us more resistant to these future conditions, and do so at the same time with proposals that take into account the low environmental impact and the health of people.

Arqbag is a young architecture studio that began its activity in 2013, and was formalized as a non-profit cooperative in 2017. Since the beginning they have maintained a strong link with the university (ETSAV – UPC), establishing their workspace in the same campus where they trained, as well as the collaboration and leadership of subjects and projects that are developed, a constant contact with research and innovation.

Its activity is articulated through three complementary vectors: social, environmental and material, through three lines of action within the cooperative: participation, environmental consultancy and architectural design.

It is a company positioned in the sector as an expert in technological innovation thanks to its direct contact with the Polytechnic University of Catalonia. They develop and advise energy efficiency and low environmental impact projects in the construction sector.

Edra arquitectura Km0 is an architecture studio specialized in efficient and low environmental impact architecture that was born in 2003 rooted in Ayerbe, a town in the province of Huesca. Edra works in all the Catalan and Aragonese provinces participating in the development of rural areas and their communities, from a global and sustainable vision, focused on comfort, energy efficiency and design with local materials and low ecological footprint. She has a research experience from the EdraLab laboratory itself develops materials based on soil and natural fibers that she implements in her projects.

It is a company positioned as an expert in projects and construction works with earth within the construction sector. In addition to developing them, it also advises energy efficiency and low environmental impact projects built with earth.

—www.arquitectura.edraculturaynatura.com

Coeco is a family work cooperative created in 1980 and constantly evolving. They are dedicated to the world of construction, restoration and facilities of all types of buildings.

They believe in the combination of Mediterranean wet constructions and Central European dry ones to carry out efficient projects, respectful of the environment and the health of people. In this sense, they are always open to combining different techniques and solutions in each project, betting decisively on combining earth and wood in the same project.

It is a company positioned in the sector as an expert in bioconstruction, developing works with natural materials such as earth and wood. They have built projects of all scales with these types of materials.

Arqbag and COECO, we have participated jointly in the SAVASCO project co-financed by INTEREG POCTEFA (to find constructive solutions based on the reuse of agri-food waste from the cultivation of corn and sunflower, through a transversal team France - Andorra - Spain). And together with Edra, they have carried out a Singular Project for the research of construction with prefabricated earth at the national and European level until the definition of Crua.

Photography of the visit to the Terrio workshop, during the Singular Project. the Terrio workshop, during the Singular Project.

Photography of the visit to Robin Vincent, during the trip around Rhone-Alps, Singular Project.

Photography of the visit to the Lehm Ton Erde amd Erden workshop, during the Singular Project.

Photography of the visit to Amàco and the Grands Ateliers, during the Singular Project.

We look at the rural environment, which has been systematically devalued and deprived of infrastructures and services as a result of an excessive vision of the city, which has accentuated and aggravated its progressive abandonment and depopulation.

Therefore, it seems strategic to explore the possibilities of rethinking, reorienting and relocating economic activities also in the primary and industrial sectors towards a perspective of proximity, with low energy content and at the same time allowing the activation and networking of the whole territory.

Thank you for cooperating!

The cooperative crua exists thanks to all the people who have supported it. You're one now. Thank you!

Remember that you can deduct up to 80% of your contribution, calculate it here.

> 01 Co-financiers

You're already a patron!

Thank you for taking the step! We will include your name in the list of patrons of our website.

Remember that you can deduct up to 80% of your contribution, calculate it here.

> 00 Co-financiers

Bring crua with you.

Cooperative spirit! You will receive a totebag made from organic and fair trade cotton.

Remember that you can deduct up to 80% of your contribution, calculate it here.

> 08 Co-financiers

Dress proud of commitment.

Thank you for your contribution! You will receive a totebag and a t-shirt made from organic and fair trade cotton.

Remember that you can deduct up to 80% of your contribution, calculate it here.

> 12 Co-financiers

Come and see your contribution!

Do not worry, you will not be left without a bag and t-shirt, but you will also be able to enjoy a visit to the crua facilities, which will have been possible thanks to you, plus the visit to an earth project by the team.

Remember that you can deduct up to 80% of your contribution, calculate it here.

> 12 Co-financiers

Become an earth rammer.

Join us in the transformation of the construction sector. With your contribution, you have not only helped make this transformation ever closer, but you will learn to formulate and ram a block of compacted earth!

Remember that you can deduct up to 80% of your contribution, calculate it here.

> 03 Co-financiers

Rething your place where you live.

You seem to be committed to the environment! Thank you for your contribution! We will help you think about how to improve climatically the place where you live, enjoy a personalized advice for your home or your place of work.

Remember that you can deduct up to 80% of your contribution, calculate it here.

> 01 Co-financiers

Experience in bioconstruction.

Together we make the change! We are so grateful that we invite you to a workshop of formulation and technique of rammed earth wall, and we will also help you think about how to climatically improve the place where you live, enjoy personalized advice from your home or your workplace. Don't worry, you will also receive a totebag and a t-shirt made from organic and fair trade cotton.

Remember that you can deduct up to 80% of your contribution, calculate it here.

> 01 Co-financiers

Project draft.

Are you solidary and also have a space to rehabilitate or build? With your contribution you have achieved a draft project of bioconstruction of the space of your dreams! Once the campaign is over, we will meet to start projecting.

Remember that you can deduct up to 80% of your contribution, calculate it here.

> 00 Co-financiers

Draft and basic project design.

Let's work together! Thank you very much for wanting to be part of the project, your space will be a pilot space of our blocks, soon you will be able to enjoy a space made to measure of your needs and most importantly, of earth!

Remember that you can deduct up to 80% of your contribution, calculate it here.

> 00 Co-financiers

Crua received one of the "Reeixim l'OESST 2024" awards from Ponent Coopera. The awards aim to recognize and support the creation of new cooperative in